SAB-profiel › News › All about insulation of SAB panels and profiles

All about insulation of SAB panels and profiles

Insulated sandwich panels

Insulated sandwich panels have been used as a construction product for many years. They consist of an outer and inner steel skin with a layer of insulating PIR foam in between. Insulated sandwich panels are ideal when fast construction is required or when high insulation values are important. They are an economical choice, score highly in terms of sustainability, and their low weight makes them suitable for many applications.

From an aesthetic point of view, insulated SAB sandwich panels offer great design freedom. They are available in many shapes, thicknesses, coatings, and colors.

Insulated façade panels

Insulated façade panels are panels specifically designed for façade applications. The façade panels include an insulation layer; in our sandwich panels this is PIR foam. It is a ready-to-use construction solution.

In our factory in Geldermalsen, we produce these insulated façade panels. They consist of two metal sheets with PIR foam in between on the inside. In this way, an insulated façade panel is created.

SAB supplies the following sandwich panels for façades:

- with visible fastening (W) in various linings LL, M8, M16, TL, and SL and different thicknesses

- with concealed/hidden fastening (WB) in various linings LL, M8, M16 and thicknesses

- carrier panels in W and WB versions as a load-bearing layer for any desired appearance

For any hall, shed, or barn with a pitched or sloping roof, insulated roof panels are the ideal solution. Roof panels are suitable for both new construction projects and (asbestos) renovation projects.

SAB insulated roof panels combine the best features. They are essentially prefabricated building elements for fast and trouble-free installation with minimal risks on site, lightweight construction, and excellent insulation values. In addition, a very tight and clean overlap is possible for all roof panels.

SAB supplies insulated roof panels with:

- 3-crown trapezoidal / TL profiling in 5 thicknesses: 70, 90, 110, 130, and 160 mm

- corrugated / SL profiling in thicknesses 83, 120, and 160 mm

- both options are also available in an ECO version with aluminum foil on the inside instead of steel

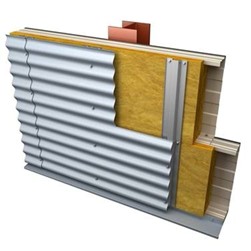

Insulated façade cladding build-up

In our factory in IJsselstein, we manufacture profiled façade sheets as well as liner trays. This allows an insulated façade to be created as a build-up system.

A build-up system with liner trays, insulation (stone wool, PIR, or EPS), and an external façade sheet is chosen when high requirements are set for acoustics, fire safety, or industrial, flexible, and demountable construction.

SAB supplies profile sheets for this purpose in various designs and heights:

- profile sheets in trapezoidal or sinusoidal/corrugated shapes

- design profile sheets

- liner trays

SAB levert hiervoor profielplaten in verschillende uitvoeringen en hoogten

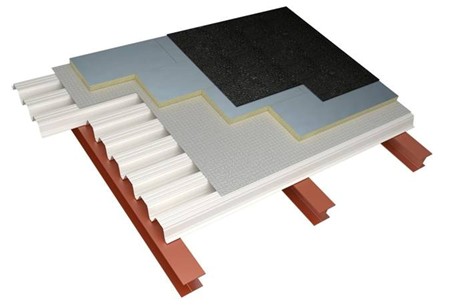

Insulated roof deck build-up

The insulated roof deck build-up is the solution for flat roofs. The steel roof sheets form the first layer in this build-up.

SAB offers various heights of warm roof deck sheets for this purpose. The term “warm” in our extensive range refers to the function of the profiles as load-bearing sheets for insulated roofs.

This is the standard for hall and industrial construction in the Netherlands and Belgium. The sheets allow large spans, exceeding 10 meters if required. The most popular heights are 106R, 135R, and 158R.

For more information about all possibilities, please also check out our projects!